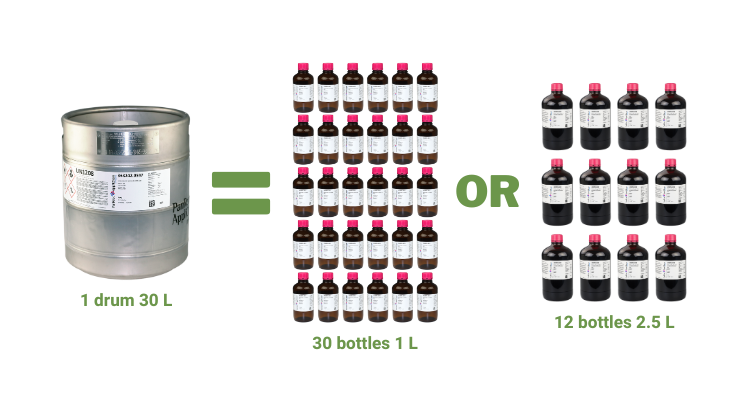

It also involves a significant saving in the consumption of packaging materials as a result of the long-lasting and resistant nature of stainless steel containers, which therefore simplifies laboratory waste management.

To guarantee the solvent quality, the empty drum is cleaned, filled with solvent and controlled on an individual basis.

We have a wide range of AISI 304 stainless steel containers available, from 10 to 1,000 liters capacity, so you can choose the most appropriate type of drum, based on consumption and available space. All containers are UN-approved for the storage and transportation of dangerous goods.

Main advantages of working with returnable containers

-

Environmentally friendly

Reduced consumption of other types of non-reusable packaging.

● Energy savings.

● Preservation of ecosystems. -

Significant saving

● Reduction of packaging disposal costs.

● For a given amount of solvent, the storage volume is smaller. -

Safety

High quality stainless steel.

● No risk of breakage compared to a glass container.

● Container resistant to temperature changes. -

Guranteed quality

● Container inert to solvent.

● The solvent quality remains unchanged. -

Easy, flexible, and convenient solvent handling

● Possibility of taking the solvent from outside the laboratory through direct connections to equipment such as HPLC (minimizing vapor emissions).

● Permits the construction of a central supply system.

● Variety of dispensing systems pursuant to user needs: Manual pressurizing or connection to an inert gas source.

● Level sensor for 200 L and 1000 L.

Recommended consumption

| DRUM VOLUME | RECOMMENDED CONSUMPTION (LITRES/YEAR)* |

| 10 L | 250 L |

| 30 L | 500 L |

| 200 L | 2000 L |

| 1000 L | 5000 L |

| * Check available sizes for each solvent |

The following are the most common types of returnable stainless steel containers available. If you do not find what you need, please contact us.

Most common returnable stainless steel containers

-

10 L

GL 45- thread, 2.4 kg, max. 0.3 bar admissible.

Accessories: withdrawal system for manual pressurizing. -

30 L - System 1

Stackable, central bung 2" Tri-Sure, 10 kg, max. 5 bar admissible.

Accessories: withdrawal system for manual or inert gas pressurizing. -

30 L - System 2

Stackable, central bung 2" Tri-Sure, 10 kg, max. 5 bar admissible.

Accessories: withdrawal system for inert gas pressurizing. Suitable for Duck Chain Principle. -

30 L - System 3

Stackable, central bung 2" Tri-Sure, 10 kg, max. 5 bar admissible.

Accessories: withdrawal system for inert gas pressurizing. Suitable for ASECOS safety cabinets type 90. -

200 L

43 kg, max. 3 bar admissible.

Customized accessories according to user needs. -

1000 L

215 kg, max. 3 bar admissible.

Customized accessories according to user needs.